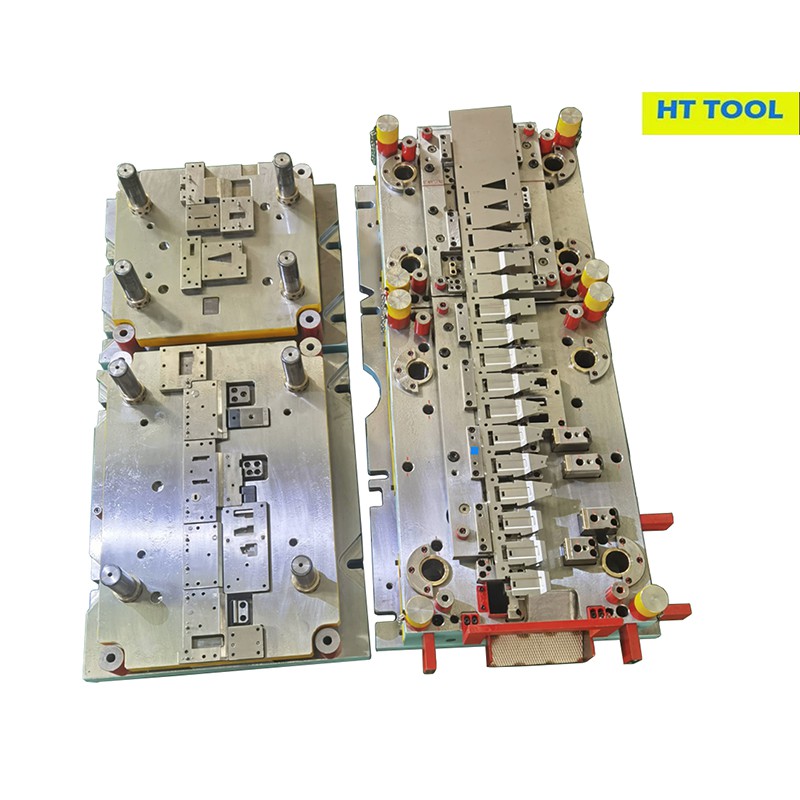

Hlau stamping cuab yeej thiab tuag

Cov khoom loj: 3100L * 950W * 650h

Cov khoom siv: carbon hlau, hlau hlau, phaj txhuas, tooj daj, tooj lossis galvanized ntawv hlau thiab lwm yam.

Khoom Taw Qhia

Ntawm ht twj thiab tuag, peb ua tshwj xeeb hauv cov cuab yeej zoo hlau hlau zoo nkauj thiab tuag tsim rau qhov tseeb, kav dej. Peb cov kev txhim kho kev txhim kho cov ntsiab lus rau kev lag luam xws li kev lag luam, aerospace kev tsim khoom, ua kom muaj zog thiab siv zog ua kom muaj zog ntau lawm ntawm cov hlau sib xyaw.

Khoom Qhia Txog Khoom

|

Khoom npe |

Hlau stamping cuab yeej thiab tuag |

|

Yam khoom No. |

Htsd -007 |

|

Cov khoom loj |

3100L*950W*650H |

|

Khoom |

Carbon Steel, Stainless hlau, hlau Stainless, txhuas phaj, tooj dag, tooj liab lossis galvanized ntawv hlau thiab lwm yam. |

|

Cov Khoom Thickness |

{{0 {0}}. {5-8 mm los yog customized |

|

Machining Txheej Txheem |

Milling, sib tsoo, tho txawv, cnc, EDM, kev ua yeeb yaj kiab, precision tiaj milling |

|

Nias sim-tawm |

200-800 t Nias Machine |

|

Kev kuaj xyuas |

CMM, 3D Laser Scanner, Alloy Analyer, Micro-Hu Nkauj, Lub Zeem Muag Khoom Muag |

|

Txoj Kev |

Xuas nrig ntaus, pam vov, tho kev, tsim, sib sib zog nqus |

|

Precision Tseeb |

Siab Precision Machining, Min. {0. 02 |

|

Tus qauv tiv thaiv |

Misumi, punch, fibro, dayton, danly thiab lwm yam. |

|

Nto Kho |

Zinc Plated, Hmoov Coated, Pleev xim, Polishing, Txhuam Hniav, Txhuam Hniav, Chrome, Sandblasting, thiab lwm yam. |

|

Tshuab Khoom Siv |

Cnc, edm, argie charmilles, milling tshuab, 3dcmm, |

|

Logo Txoj Kev |

Laser engraving, cnc engraving |

|

Daim Ntawv Thov Kev Lag Luam |

Automotive, Khoom siv hauv tsev, electronics, Aero-chaw |

|

Tsim Cov Ntaub Ntawv Hom |

Kauj ruam, DWG, CAD, STP, PRT, Catia, PDF |

|

Kuaj xyuas qhov chaw |

Peb lub tshuab ntsuas sib koom ua ke, micrometer, calipers, 3D scanner |

|

Ntau Lawm Lub Peev Xwm |

150sets txhua xyoo rau kev vam meej cov ntawv tsim cov ntawv hlau |

1, Peb Lub Peev Xwm

CAE Kev Ntsuam Xyuas: Los ntawm simulating cov txheej txheem stamping, CAE essional pab txheeb xyuas cov teeb meem muaj peev xwm xws li cov khoom siv thinning, los yog rwgetback ua ntej cov hlau stamping cuab yeej thiab tuag mus rau ntau lawm. Qhov kev pom zoo no tso cai rau cov tuam txhab tsim qauv zoo thiab ua kom zoo dua cov khoom siv tsis zoo thiab ua kom zoo dua qub cov khoom siv tsis zoo thiab ua kom zoo dua hlau stamping hloov tuag thiab lwm cov txheej txheem stamping. Concurrent engineering, cov qauv tsim qauv, thiab kev koom tes thaum ntxov tuaj yeem pab ua kom cov txheej txheem ua kom luv-lub sijhawm.Qhov no yog piv txwv li peb txoj kev sim ua hlau lom zem:

CAE simulation

3D hloov tuag simulation

Hlau stamping twj thiab tuag tsim qauv: Hauv lub tuam txhab tsim chaw tuam txhab, peb muaj peev xwm los muab peb cov neeg siv khoom nrog tag nrho cov kev pabcuam. Cov kws ua engineers siv autoform kom ntseeg tau lub peev xwm ntawm kev tawg thiab kev tshawb fawb, rebound, nyiaj them, videos, thiab lwm yam. Txog rau kev tsim cov 3D / 2D tsim qauv tsim, peb cov neeg tsim qauv (X 90) siv cov software.

3D CAV HIAV TXUASkev tsim ua

Hlau stamping cuab yeej thiab tuag yuav cov txheej txheem

Vim li cas thiaj xaiv peb rau koj cov hlau stamping ntau lawm

Vim li cas thiaj xaiv peb cov hlau Stamping & Tuag Pab?

✔ Kev Cai Engineering- Cov qauv tsim qauv kom tau raws li cov lus qhia tseeb

✔ Siab Precision- Advanced CNC Machining rau nruj tiv thaiv

✔ Yam ruaj khov- Cov ntaub ntawv hwm hwm thiab kev kho cua sov rau kev txuas ntxiv lub neej

✔ Nrawm tig- Kev tsim muaj txiaj ntsig nrog kev txwv tsawg

✔ Nqi-Zoo- Kev daws teeb meem zoo kom txo cov nqi ntev ntev

Peb Daim Ntawv Pov Thawj Siv Iso9001: 2015 thiab ITF 16949: 2016

Peb cov txheej txheem txaus rau hlau satmping cuab yeej thiab tuag ntau lawm

Peb cov cuab yeej siv npe rau hlau stamping cuab yeej thiab tuag ntau lawm

|

Yam khoom No. |

Cuab tam |

Qhov tshwj xeeb (hli) |

Qw |

|

1 |

Xovxwm Tshuab |

800 T(4200*1900*1200) |

1 |

|

2 |

400 T (3300*1500*750) |

1 |

|

|

3 |

200 T (2400*840*550) |

1 |

|

|

4 |

Peb-hauv-ib tug pub mis |

Dav 6 {0 0mm, thickness 0. 5- 4. 5 hli |

1 |

|

5 |

Peb-hauv-ib tug pub mis |

Dav 12 {0 0 mm, thickness 0. {}. 0mm |

1 |

|

6 |

Cnc |

2500*1700*1000 |

1 |

|

1100*650*750 |

1 |

||

|

800*500*550 |

3 |

||

|

7 |

Nto sib tsoo tshuab |

1000*600 |

1 |

|

8 |

800*400 |

1 |

|

|

9 |

Los Ntawm Txhais Tes Sib Tsoo Tshuab |

150*400 |

2 |

|

10 |

Ntsug drilling tshuab |

ф1~32 |

3 |

|

11 |

Radial Drilling Tshuab |

¢1~32 |

1 |

|

12 |

¢1~50 |

1 |

|

|

13 |

Milling tshuab |

1150*500*500 |

2 |

|

14 |

Li Qub Hlau Txiav Machine |

800*630 |

1 |

|

15 |

500*400 |

4 |

|

|

16 |

Ceev chaws Khij Hlau Txiav Machine |

800*500 |

1 |

|

17 |

500*400 |

1 |

|

|

18 |

Tus mob stoma edm |

300*200 |

1 |

|

19 |

3D scanner |

650*550 |

1 |

Cov FAQ

Q: 1. Dab tsi yog cov hlau stamping cuab yeej thiab tuag?

A: Ib qho khoom siv hlau hlau thiab tuag yog qhov ua kom precision siv hauv stamping ntu tsim los txiav, cov duab, lossis tsim cov ntawv hlau rau hauv cov ntu tshwj xeeb. Tus tuag ua yeeb yam li pwm, thaum lub xov tooj stamping siv rau tsim cov khoom siv uas xav tau.

Q: 2 2. Hom dab tsi uas koj muab?

A: HT Tool & Tuag muab ntau yam hlau stamping cuab yeej thiab tuag, suav nrog:

Kev Ua Si Tuag (rau qhov nrawm nrawm, ntau theem kev sib sau)

Hloov chaw tuag (rau cov nyom, qhov chaw loj)

Compound tuag (rau kev sib xyaw ua ke thiab tsim nyob rau hauv ib qho stroke)

Blanking tuag (rau meej pav-ntu txiav)

Q: 3. Dab tsi cov ntaub ntawv tuaj yeem ua tiav nrog koj cov nyiaj muas noj?

A: Peb cov tuag tau tsim los ua haujlwm nrog ntau yam hlau, suav nrog:

Hlau (Txias-Rolled, Stainless, thiab lwm yam)

Tooj dawb

Tooj Tooj & Brass

Muaj Zog-Zog Alloys

Q: 4. Koj ua li cas thiaj paub tseeb lub sijhawm ntawm koj cov hlau stamping thiab tuag?

A: Peb siv cov cuab yeej cuab tam zoo (D2, A2, carbide) thiab siv cov kev kho cua sov, thiab ua kom zoo nkauj (xws li ua kom lub neej ua haujlwm.

Q: 5. Koj ua haujlwm dab tsi nrog koj lub cuab yeej ua haujlwm thiab tuag?

A: Peb cov kev daws teeb meem txhawb kev lag luam xws li:

✅ Qhov Chaw (Cov Qauv Txheej Txheem, Chassis, Rooj Zaum Rooj, nkhaus, Connectors)

✅ Electronics (Shielding, Cov Neeg Hu

✅ Aerospace (Cheebtsam txheej txheem)

Muaj Khoom Siv (Cov Tsev, Panels)

Q: 6. Koj puas tuaj yeem hloov kho tuag rau qee qhov kev xav tau?

A: Yog! Ntawm ht twj thiab tuag peb muab tag nrho cov kev cai tuag raws li koj txoj kev kos duab, cov khoom xav tau.

Q: 7. Dab tsi yog cov txhuas lub sij hawm rau kev cai sib tw tuag?

A: Cov sij hawm coj sib txawv raws cov nyom raws li cov nyom, tab sis peb ua kom nrawm nrawm rau nrawm nrawm (feem ntau {{part wit} lub lis piam rau cov qauv tuag).

Q: 8. Koj yuav tswj tau zoo li cas tswj hwm kev tuag tsim tau?

A: Peb siv CNC Machining, CMM tshuaj xyuas, thiab kev sim nruj thiab nruj ua kom txhua tus tuag ua raws li kev ua kom thev taus thiab ua tau zoo.

Q: 9. Koj puas muab cov cuab yeej tu thiab kho cov kev pab?

A: Yog, ntawm HT Tool thiab tuag peb muab kev tu tuag, hlwv tawm, thiab kho kom ntau rau kev ua haujlwm ntev thiab ua tau zoo.

Cim npe nrov: Hlau stamping cuab yeej thiab tuag, Tuam Tshoj hlau stamping twj thiab tuag manufacturers, chaw muag khoom, Hoobkas

Koj Tseem Yuav Zoo Li

Xa kev nug