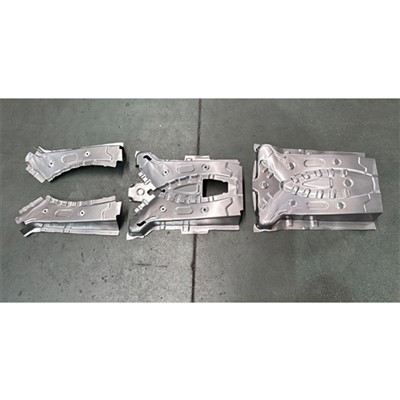

Progressive Hlau Stamping

Khoom loj: 2640x935x730mm

Khoom siv: Carbon steel, stainless hlau, txhuas phaj, tooj dag, tooj liab lossis galvanized ntawv hlau thiab lwm yam.

Khoom Specification

|

Khoom npe |

Progressive hlau stamping |

|

Yam khoom No. |

HTSD-001 |

|

Khoom loj |

2640x935x730mm |

|

Khoom siv |

Carbon steel, stainless hlau, txhuas phaj, tooj dag, tooj liab lossis galvanized ntawv hlau thiab lwm yam. |

|

Khoom thickness |

0 5-8mm lossis customized |

|

Kev kho saum npoo |

Zinc plated, hmoov coated, painting, polishing, txhuam, chrome plating, anodizing, sandblasting, thiab lwm yam. |

|

Cov cuab yeej siv tshuab |

CNC, EDM, Argie Charmilles, Milling Tshuab, 3DCMM, |

|

Txoj Kev Logo |

Laser engraving, CNC engraving |

|

Daim ntawv thov kev lag luam |

Automotive, Khoom Siv Hauv Tsev, Electronics, Aero-space |

|

Ntim |

Ntoo lub thawv los yog ntawm koj qhov kev thov |

|

Chaw kuaj mob |

Peb lub koom haum ntsuas tshuab, Micrometer, calipers, 3D scanner |

|

Muaj peev xwm tsim tau |

150sets txhua xyoo |

Taw qhia txog Progressive Hlau Stamping

Progressive Hlau Stamping Tuag yog ib txoj kev ua hlau uas muaj peev xwm suav nrog kev xuas nrig ntaus, npib, khoov thiab ob peb lwm txoj hauv kev hloov kho cov khoom siv hlau, ua ke nrog kev pub mis tsis siv neeg.

Txij li thaum ua hauj lwm ntxiv yog ua tiav nyob rau hauv txhua "chaw nres tsheb" ntawm qhov tuag, nws yog ib qho tseem ceeb uas lub sawb yuav advanced precisely kom nws dlhos nyob rau hauv ob peb txhiab ntawm ib nti thaum nws txav los ntawm chaw nres tsheb mus rau qhov chaw nres tsheb. Cov mos txwv zoo li tus los yog conical "pilots" nkag mus rau yav dhau los pierced puag ncig qhov nyob rau hauv lub sawb kom paub tseeb tias qhov kev sib raug zoo no txij li thaum lub tshuab pub mis feem ntau tsis tuaj yeem muab qhov tsim nyog rau qhov ntev pub.

Cov txiaj ntsig dab tsi cov neeg siv khoom tau txais los ntawm peb cov khoom

Progressive hlau stamping yog cov txheej txheem tsim tau zoo thiab muaj ntau yam siv los tsim ntau yam hlau, xws li qhov chaw pib, khoom siv hluav taws xob, khoom siv hauv tsev hlau thiab lwm yam .. Thaum nws los txog rau kev nce qib hlau stamping, muaj ntau yam txiaj ntsig:

- Ua haujlwm siab: Progressive tuag tso cai rau ntau qhov kev ua haujlwm ua haujlwm hauv ib leeg xovxwm, rau kev ua haujlwm zoo li qub, lub peev xwm ntau lawm tuaj yeem ncav cuag 30 strokes ib feeb, yog li nce cov nqi ntau lawm piv rau cov txheej txheem stamping ib txwm ua.Nrog ntau yam kev ua haujlwm ib txhij, kev vam meej tuag. stamping maximizes xovxwm uptime thiab tag nrho cov khoom tsim tau, ua rau cov zis ntau dua.

- Nqi-zoo: Txawm hais tias tus nqi pib pib, kev nce qib tuag stamping tuaj yeem raug nqi ntau dua rau cov khoom ntim ntau lawm vim nws qhov nrawm thiab ua haujlwm tau zoo.Yog li qhov no tuaj yeem txuag tau ntau tus nqi ntau lawm thaum cov neeg siv khoom nce qib hlau stamping.

- Precision thiab raug: Progressive dies yog engineered los ua qhov tseeb thiab zoo ib yam stamping kev khiav hauj lwm, kom ntseeg tau tias uniformity thiab raug nyob rau hauv cov khoom tsim.Yog li no yuav ua rau kom muaj kev sib tw ntawm stamping qhov chaw rau cov neeg siv khoom.

- nyuaj: Progressive hlau stamping tuag tuaj yeem ua raws li qhov nyuaj geometries thiab cov yam ntxwv, suav nrog kev khoov tsis sib xws, cov ntaub ntawv, thiab perforations, ua rau lawv zoo tagnrho rau kev tsim cov khoom siv nrog kev xav tau tsim. kom tau raws li qhov yuav tsum tau ua.

- Txo cov khoom pov tseg: Cov xwm txheej ntawm cov txheej txheem tuag stamping txo qis cov khoom pov tseg piv rau lwm cov txheej txheem tsim khoom, ua rau cov nqi txuag thiab cov txiaj ntsig ib puag ncig.Qhov no yuav txuag cov khoom siv rau cov neeg siv khoom.

- Scalability: Progressive tuag stamping yog yooj yim scalable kom haum rau ntau ntau lawm ntim, ua rau nws haum rau ob qho tib si me me thiab loj-scale manufacturing operations.Customer tuaj yeem kho cov khoom raws li qhov sib txawv.

- Ntev kev pab cuam lub neej: Progressive hlau stamping yuav tsum tau cov ntaub ntawv zoo raw khoom thiab cov qauv txheem.Main cov ntaub ntawv muaj xws li D2, YG15, DC53, SKD11, D2, SKH-9, thiab SKH-51.Nrog siab zoo raw khoom, qhov no ho nce kev pab cuam lub neej ntawm kev vam meej hlau stamping tuag.Qhov kev pab cuam lub neej yuav ua tau mus txog 2 lab strokes rau qhov loj.

Cov txheej txheem ntau lawm ntawm Progressive hlau stamping

Progressive hlau stamping yog ib qho kev txiav thiab tsim cov txheej txheem uas siv cov tuag uas muaj ntau qhov chaw nres tsheb hlau uas ua haujlwm ib txhij ntawm ib sab raws li nws tau nqa los ntawm lub coiled sawb. Tshwj xeeb, cov txheej txheem ua raws li cov kauj ruam no:

- Tooling creation los ntawm toolmakers. Cov kws tshaj lij cov cuab yeej yuav tsum tsim cov cuab yeej, lossis cov txheej txheem tuag, raws li qhov xav tau ntawm daim ntawv thov tshwj xeeb. Txij li cov txheej txheem tuag no muaj tag nrho cov cuab yeej tsim nyog los nqa tawm ntau lawm, cov cuab yeej tsis tas yuav hloov pauv ntawm kev ua haujlwm.

- Muab qhov tuag. Thaum tsim, cov tuag yuav tsum muab tso rau hauv lub stamping xovxwm. Lub tuag qhib thaum lub stamping xovxwm txav mus, thiab nws kaw thaum lub stamping xovxwm txav mus.

- Load lub workpiece. Tom ntej no, lub workpiece yuav tsum tau muab tso rau hauv qhov tuag. Lub workpiece txav mus los ntawm qhov tuag thaum nws qhib, yog incrementally pub rau hauv tuag nrog txhua tus xovxwm stroke.

- Ua haujlwm. Cov tuag tuaj yeem hloov cov khoom ua haujlwm ntau yam, xws li embossing, npib, khoov, txiav, thiab lwm yam. Thaum qhov tuag kaw, nws ua nws txoj haujlwm ntawm lub workpiece.

- Ntu ejection. Thaum lub workpiece txav mus los ntawm txhua qhov chaw ua haujlwm thiab tau coj los ntawm nws qhov kawg cov duab thiab qhov loj me, cov khoom tiav raug tshem tawm ntawm qhov tuag. Tom qab ntawd lawv tuaj yeem raug txiav los ntawm cov cab kuj.

Peb Muaj Peev Xwm

CAE Analysis: Kev tsom xam CAE raug pab txhim kho qhov zoo thiab ua kom zoo dua qub hlau stamping hloov pauv tuag thiab lwm cov txheej txheem stamping tooling. Concurrent engineering, kev tshuaj xyuas cov khoom tsim, thiab kev koom tes thaum ntxov tuaj yeem pab txo lub sijhawm ua haujlwm.Qhov no yog piv txwv ntawm peb cov hlau stamping CAE simulation:

Stamping tuag tsim: Hauv lub tuam tsev tsim cov cuab yeej, peb muaj peev xwm muab peb cov neeg siv khoom nrog ntau yam kev pabcuam. Engineers siv AUTOFORM los xyuas kom meej lub manufacturability ntawm stampings thiab simulation (kev kawm los ntawm cov kab nrib pleb, wrinkles, rebound, them nyiaj, yeeb yaj duab, thiab lwm yam). Txhawm rau ua tiav 3D / 2D tooling tsim, peb cov neeg tsim qauv (x9) siv UG software.

Kev tswj qhov project:Rau txhua qhov kev vam meej hlau stamping qhov project, peb yuav muab ib qhov project engineer los tswj tag nrho cov txheej txheem los ntawm lub tswv yim ntawm qhov pib mus rau kev ua tiav zoo. Peb muaj ib pab neeg tswj xyuas qhov project zoo, uas yog tus tswv muaj zog engineering keeb kwm thiab zoo ntawm kev sib txuas lus Askiv. Qhov no pab koj qhov project mus zoo thiab tswj tau zoo. Peb yuav khaws cov neeg siv khoom tshiab txog cov ncauj lus nthuav dav ntawm qhov project no los ntawm kev tshaj tawm txhua lub lim tiam thiab cov duab tshiab. Nws yog ib qho yooj yim rau cov neeg siv khoom los tswj qhov project tib lub sijhawm. Peb yuav muab cov txheej txheem siab ntawm cov neeg siv khoom los ntawm kev txhim kho tus kheej. Tsuas yog ib lub xov tooj hu, lossis e-mail, thiab koj yuav pom tias peb npaj txhij rau koj txhua lub sijhawm.

Tus nqi tsim khoom optimization: Thaum ua haujlwm zoo nrog cov neeg siv khoom los ntawm cov txheej txheem kev npaj mus txog rau kev tsim cov cuab yeej, peb ib txwm siv ntau cov peev txheej thiab kev siv zog ntawm kev siv cov khoom siv ntau tshaj plaws & xovxwm stroke thiab txo cov cuab yeej chaw nres tsheb thaum ua kom ruaj khov thiab rov ua dua.

Stamping tuag manufacturing: HT TOOL muaj peev xwm tsim cov txheej txheem hlau stamping hauv tsev kom tau raws li peb cov neeg siv khoom xav tau. Peb lub tuam tsev engineering ua haujlwm nrog peb cov neeg ua haujlwm txawj ntse los xyuas kom meej qhov zoo ntawm koj cov khoom.Cov hauv qab no yog peb cov khoom siv machining:

|

Yam khoom No. |

Khoom siv |

Specification (hli) |

QTY |

|

1 |

Xovxwm tshuab |

800 T(4200*1900*1200) |

1 |

|

2 |

400 T (3300*1500*750) |

1 |

|

|

3 |

200 T (2400*840*550) |

1 |

|

|

4 |

Peb-hauv-ib lub tshuab pub mis |

Dav 600mm, thickness 0.5- 4.5mm |

1 |

|

5 |

Peb-hauv-ib lub tshuab pub mis |

Dav 1200mm, thickness 0.5- 6.0mm |

1 |

|

6 |

CNC |

2500*1700*1000 |

1 |

|

1100*650*750 |

1 |

||

|

800*500*550 |

3 |

||

|

7 |

Nto Sib Tsoo Tshuab |

1000*600 |

1 |

|

8 |

800*400 |

1 |

|

|

9 |

Phau ntawv sib tsoo tshuab |

150*400 |

2 |

|

10 |

Vertical Drilling Tshuab |

ф1~32 |

3 |

|

11 |

Radial Drilling Tshuab |

¢1~32 |

1 |

|

12 |

¢1~50 |

1 |

|

|

13 |

Tshuab Milling |

1150*500*500 |

2 |

|

14 |

Ib txwm hlau txiav tshuab |

800*630 |

1 |

|

15 |

500*400 |

4 |

|

|

16 |

Fast Hlau Tej Tshuab |

800*500 |

1 |

|

17 |

500*400 |

1 |

|

|

18 |

Stoma EDM |

300*200 |

1 |

|

19 |

3D Scanner |

650*550 |

1 |

Stamping tuag tryout: Peb muaj Mechanical Press ntawm 200T txog 800T

200T Mechanical Press

Max rooj loj: 2400 * 840 * 550mm

400T Mechanical Press

Max rooj loj: 3300 * 1500 * 750mm

800T Mechanical Press

Max rooj loj: 4200 * 1800 * 1200mm

Kev pabcuam hauv ib lub khw: Raws li cov kws tshaj lij kev lag luam hlau stamping chaw tsim tshuaj paus nyob rau hauv Suav tooling kev lag luam nrog cov muaj peev xwm thiab muaj peev xwm loj, HT Tool thiab Die muab ib qho kev daws teeb meem rau cov neeg siv khoom los ntawm kev tsim & tsim cov cuab yeej txias & kub tsim, tshuaj xyuas fixtures thiab vuam jigs nyob rau hauv lub ntiaj teb no automotive. kev lag luam.

Kev sib piv ntawm Stamping Dies: Yooj yim vs. Compound tuag vs. Progressive hlau stamping vs. Hloov Tuag

|

Feature |

Yooj Yim Tuag |

Compound Tuag los yog Combination Tuag |

Kev vam meejhlau stamping |

Hloov Tuag |

|

Kev ua haujlwm |

Kev ua haujlwm ib leeg |

Kev ua haujlwm ntau yam (ib leeg mob stroke). Tsawg heev rau kev tsim. |

Kev ua haujlwm ntau yam (ib ntus). Me ntsis txwv rau kev tsim. Qee qhov kev kos duab nyuaj yuav xav tau kev hloov pauv tuag |

Kev ua haujlwm ntau (hloov ntawm chaw nres tsheb). Txhua txoj kev ua haujlwm yog ua tau. |

|

Chaw nres tsheb |

Ib qhov chaw nres tsheb |

Ib qhov chaw nres tsheb |

Ntau qhov chaw nres tsheb |

Ntau qhov chaw nres tsheb |

|

nyuaj |

Tsawg |

Tsawg mus rau nruab nrab |

Siab nyuaj |

Siab nyuaj |

|

Pwm kuaj thiab teeb tsa |

Yooj yim |

Nyuaj |

Nruab nrab. Modules txo qhov nyuaj thiab nce kev teeb tsa ua haujlwm. |

Feem ntau yooj yim dua li kev nce qib, tab sis yuav tsum tau hloov pauv thiab nqa cov khoom siv uas tseem nyuaj rau kev tsim. |

|

Kev ua tau zoo |

Tsawg heev |

Tsawg |

Siab heev |

Siab. qeeb tshaj qhov kev vam meej muab cov kev hloov pauv uas yuav tsum tau ua. |

|

Nqi |

Tsawg tooling nqi, siab ib feem tus nqi |

Tus nqi nruab nrab tooling, nruab nrab ib chav tsev nqi |

Cov cuab yeej siv siab, tus nqi qis heev ntawm chav tsev |

Feem ntau cov cuab yeej siab dua thiab chav tsev nqi dua li kev nce qib |

|

Ntau lawm ntim |

Tsawg ntim |

Nruab nrab mus rau siab ntim |

High ntim (tsim nyog rau kev tsim khoom loj) |

High ntim, (tsim nyog rau ntau lawm) |

|

Kev tsim nyog |

Tej yam yooj yim |

Tej yam yooj yim |

Qhov nyuaj |

Loj thiab/los yog concave qhov chaw, complex qhov chaw |

|

Cov khoom siv tus nqi |

Nruab nrab mus rau siab |

Nruab nrab mus rau siab |

Nruab nrab. Qhov xav tau rau cov tsav tsheb thiab cov neeg nqa khoom tuaj yeem txo cov khoom siv. Kev tsim qauv zoo tuaj yeem txo cov khoom seem uas tsim tawm. |

Nruab nrab mus rau siab |

|

Kev ua haujlwm dawb |

1 zog |

1 zog |

Kev ua haujlwm kawg |

Thawj qhov kev ua haujlwm |

Daim ntawv pov thawj

FAQ

Q: Yuav ua li cas ua haujlwm tuag stamping?

Q: Dab tsi yog hom hlau stamping loj?

Q: Dab tsi yog qhov kev ua haujlwm ntawm kev nce qib hlau stamping?

Q: Progressive Hlau Stamping Applications yog dab tsi?

Cim npe nrov: Tuam Tshoj Progressive hlau Stamping manufacturers, lwm tus neeg, Hoobkas

Koj Tseem Yuav Zoo Li

Xa kev nug