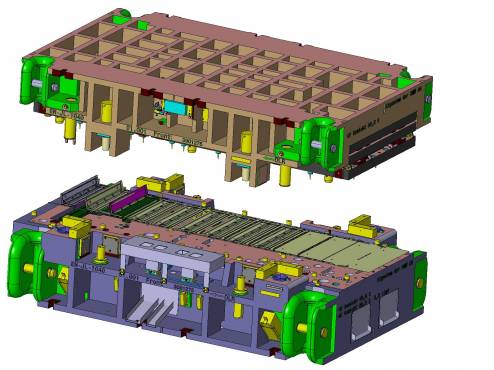

Nrog kev nce nyiaj ntawm cov neeg ua haujlwm hauv kev lag luam stamping, nws yog qhov tseem ceeb heev los txo cov nqi zog thiab cov nqi tsim khoom rau cov tuam txhab hlau stamping. Qhov kev vam meej tuag hlau stamping yog qhov tshwm sim tsis tu ncua, Nws yog ib txoj hauv kev zoo los tsim kom muaj tus nqi qis thiab ua haujlwm siab automation stamping ntau lawm kab los ntawm kev tsim cov tuag tuag. Txawm li cas los xij, kev tuag zuj zus yuav tsum muaj kev ua haujlwm siab thiab cov khoom nyuaj, nws yuav tsum tau them sai sai rau cov teeb meem hauv cov txheej txheem tsim. qhov no yuav xav tau kev tsim qauv zoo, uas feem ntau tshwm sim hauv cov hauv qab no:

1, Thaum muaj ntau qhov punch, qhov ntev ntawm lub qhov tuag yuav tsum tsis txhob loj dhau.

Rau stamping tuag nrog ntau lub siab tuag, tsim qhov sib txawv qhov siab sab sauv tuag raws li qhov sib txawv qhov ntau thiab tsawg raws li txoj hauv kev, qhov no tuaj yeem zam qhov max.value ntawm lub siab ntawm lub siab tuag tsim nyob rau hauv ib lub sij hawm yog li zoo txo qhov tuag lub punch siab, thiab txo lub zog thauj khoom ntawm lub tshuab xovxwm.Thaum stamping, lub qhov loj thawj zaug punched tom qab ntawd xuas nrig ntaus lub qhov me me.Yog xuas nrig ntaus lub qhov loj ua ntej, kom cov khoom nyem me me sab sauv tuag ua teeb meem ntawm sab sauv tuag vim yog tsis muaj zog.

2, Progressive tuag sim ntxiv thaiv, notch Fabkis thiab pitch positioning ntaus ntawv.

Cov cuab yeej ua haujlwm tsis tu ncua suav nrog kho tus pin pin, coj tus pin, phau ntawv qhia phaj thiab thais Fabkis thiab lwm yam ... Hauv lub stamping, tus pin ruaj ruaj yog siv rau qhov chaw pib, thiab cov lus qhia tus pin ntsia hauv qhov tuag yog siv los xyuas kom meej qhov Qhov tseeb qhov chaw ntawm cov strips thaum cov khoom poob qis.Notch Fabkis yog siv los tswj qhov kev pub noj ntawm cov sawb, thiab qhov ntev ntawm cov lus Fabkis txoj yuav tsum sib npaug rau lub suab ntxiv. 0.05-0.5mm, kuj nyob ntawm cov strip thickness.

3, Cov lus qhia tus pin ntawm kev vam meej tuag yuav tsum tsis txhob ntev dhau

Peb yuav tsum nco ntsoov tias qhov ntev ntawm phau ntawv qhia tus pin yuav tsum tsis txhob loj dhau, ntev rau hauv phau ntawv qhia lub qhov yuav tsum tsis txhob loj dhau, txwv tsis pub, cov khoom noj tsis zoo, qhov ntev ntawm cov lus qhia pins yuav tsum yog thickness ntawm phau ntawv qhia pin kho phaj ntxiv. cov khoom thickness.

4, Qhov nyuaj thiab qhov ntev & nyias yuav tsum tsis txhob xuas nrig ntaus ib zaug hauv kev tuag.

yog tias cov txheej txheem tso cai yuav tsum tau muab faib ua ntau yam ntawm cov punches, thiab cov kauj ruam los ntawm kauj ruam rau stamping, uas tuaj yeem yooj yim dua rau tshuab lub qhov ntawm cov cuab yeej thiab txuas lub neej kev pab cuam, thiab yooj yim kho cov pwm ces txhim kho cov khoom tsim tau.

5, Tsim yuav tsum tawm tsis ua haujlwm txhawm rau kho thiab hloov cov cuab yeej tom qab

Tawm ntawm qhov chaw nres tsheb khoob ntawm qhov chaw nres tsheb nres thiab qhov kawg qhov chaw nres tsheb caij nplooj zeeg txhawm rau txhawm rau txhim kho lub phaj stripper thiab cov phaj qis qis kom txhim kho lub zog ntawm qis tuag.

6, Scraps dhia-pov thawj tsim

Hloov cov duab ntawm cov punch, nce qhov adhesion ntawm seem rau cov kab txiav punch nrog tshuab qhov V-shaped lossis dovetail jamming ntawm cov kab txiav.

tsim tsim nyog punch clearance

7, Lub sawb nyob rau hauv qhov kev vam meej tsis tuaj yeem deformed

8, Cov khoom siv nrog kev ua haujlwm ntawm kev hloov pauv sai thiab tsis muaj pov thawj